Understanding Flange Weight is crucial for Flanges Manufacturer. Flanges are essential components of pipeline systems because they offer a safe connection between pipes and other pieces of machinery. It is crucial to comprehend flange weight for a variety of reasons, such as load calculations, installation, and shipping. We’ll look at the formula and procedures in this blog post. To provide you a thorough overview of this subject, we will draw on the experience of Trimac Piping, a well-known name in the Flanges.

Trimac Piping Solutions is one of the largest Flanges Manufacturers in India and Flange Supplier in India

Understanding Flange Weight:

Flanges are crucial components in piping systems, providing essential connections and support for various equipment and pipelines. When designing or working with piping systems, it is important to have a good understanding of flange weight. In this blog post, we will delve into the factors that contribute to flange weight, explain how to calculate it, and highlight the significance of considering flange weight in engineering and installation processes.

Let’s first define what the flange weight means before moving on to the computation process. The term “flange weight” describes the whole weight of a flange, including the weight of the body, bolt holes, gasket, and any other parts. The weight might change based on the size, material, and pressure class of the flange and is commonly stated in pounds (lbs) or kilogrammes (kg).

Calculating Flange Weight Formula:

To calculate the flange weight, the following formula is commonly used:

Flange Weight (in lbs or kg) = [(OD – Thickness) x Thickness x K] / Conversion Factor

Where:

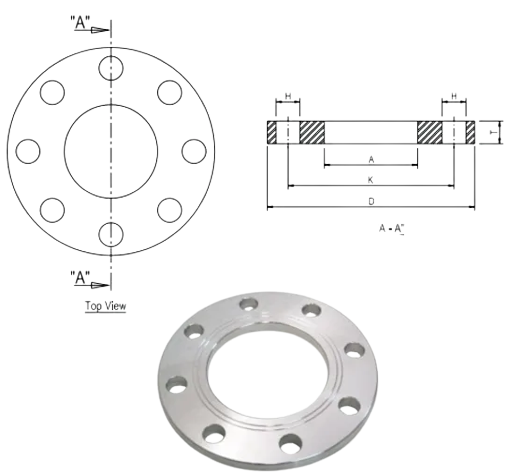

OD: Outer diameter of the flange

Thickness: Thickness of the flange

K: A constant depending on the flange type

Conversion Factor: A conversion factor to obtain the desired weight unit (lbs or kg)

Different types of flanges have varying values for the constant “K.” Here are the common values for different flange types:

Slip-On Flanges: K = 0.68

Weld Neck Flanges: K = 1.00

Socket Weld Flanges: K = 0.79

Lap Joint Flanges: K = 0.92

Threaded Flanges: K = 0.87

Blind Flanges: K = 0.61

Note: The values mentioned above are approximate and may vary depending on the specific standards and specifications of the flanges being used. Always refer to the relevant industry codes or consult with professionals for accurate values.

Step-by-Step Calculation Process:

To calculate the flange weight accurately, follow these steps:

Step 1: Obtain the flange dimensions:

Measure the outer diameter (OD) of the flange.

Determine the thickness of the flange.

Step 2: Determine the flange type:

Identify the type of flange being used (slip-on, weld neck, socket weld, lap joint, threaded, or blind).

Step 3: Determine the constant (K) value:

Refer to the values mentioned above for different flange types and note down the appropriate constant (K) for your flange type.

Step 4: Select the desired weight unit:

Determine whether you want the weight to be expressed in pounds (lbs) or kilograms (kg).

Step 5: Apply the formula:

Plug in the values obtained from steps 1 to 4 into the flange weight formula mentioned earlier.

Calculate the flange weight using the formula.

Conclusion:

For many technical applications, determining a flange’s weight is essential. You may precisely compute the flange weight by using the techniques and formula described in this blog article while taking into account the flange type, dimensions, and required weight unit. For accurate measurements and computations, always be sure to adhere to the relevant industry standards and seek out experts. Trimac Piping can offer insightful advice and help when determining flange weight for your particular needs thanks to its expertise in the area.

We are also

Flanges Manufacturers in Mumbai

Flanges Manufacturers in Chennai